What makes good stage lighting?

Many stage lighting manufacturers in the world. It isn’t easy to choose the supplier for some clients. Good stage lighting can make a big difference in creating wonderful events.

What are the factors of good stage lighting? Let’s read the below article to find the answer.

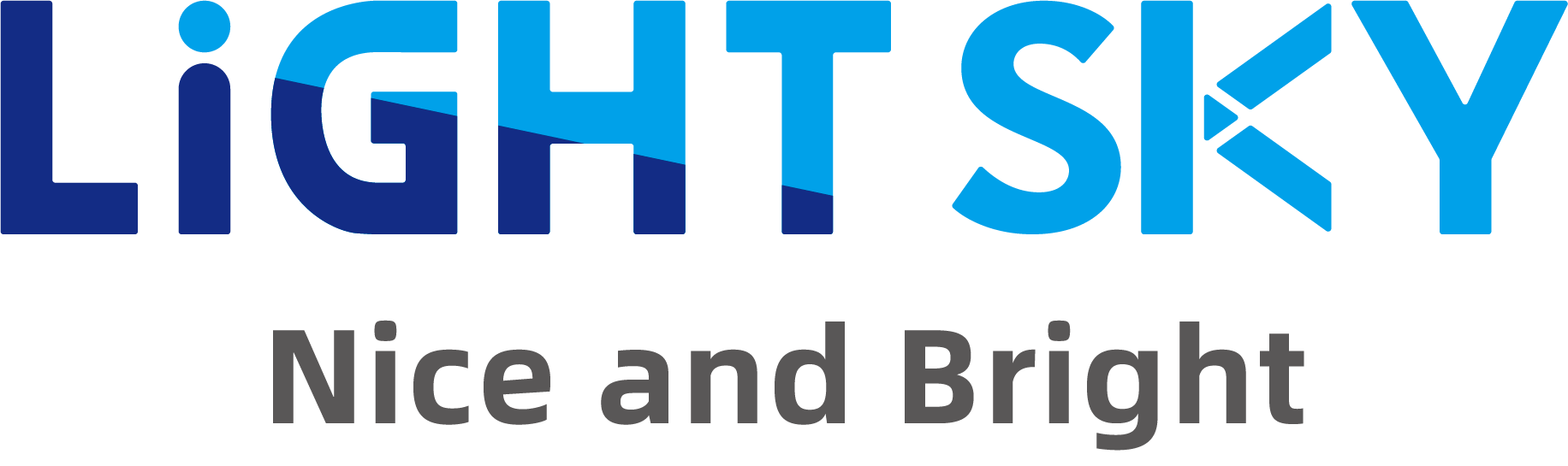

1.How to improve termal dissipation system?

For smart stage lighting, Thermal dissipation system likes human being’s respiratory system. A set of qualified thermal dissipation system not only stabilize the lighting fixture, but also longer the lighting fixture’s life span. For this, LIGHT SKY have made countless experiments and improvements. And we found that copper pipe with Fan-shaped structure across thermal dissipation module’s finned pipe generate excellent result. So, LIGHT SKY integrated the thermal dissipation copper. Module’s aluminum base with finned pipe the thickness of the finned pipe is 0.5MM. The distance between each finned pipe is 2.0MM, adjust the layout of dissipation fan and move the light source driver into the low temperature area. In above way, the whole termal dissipation system effect improves 31.5%.

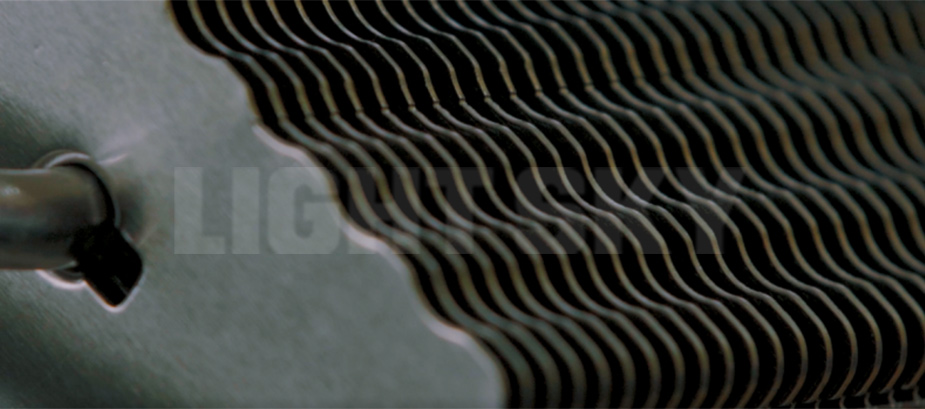

2.How to improve light source’s efficiency?

The output quality is always the challenge of R&D people. To make the beam and color more sharp, more bright and more pure. LIGHT SKY adopts the high transmittance and high percision optical lens, and coating the lens with high definition procedure. In additional, module precision cutting and skilled worker assembling which maximum decrease the design tolerance and insure the structure of optical lens’ scientific nature and standardization.

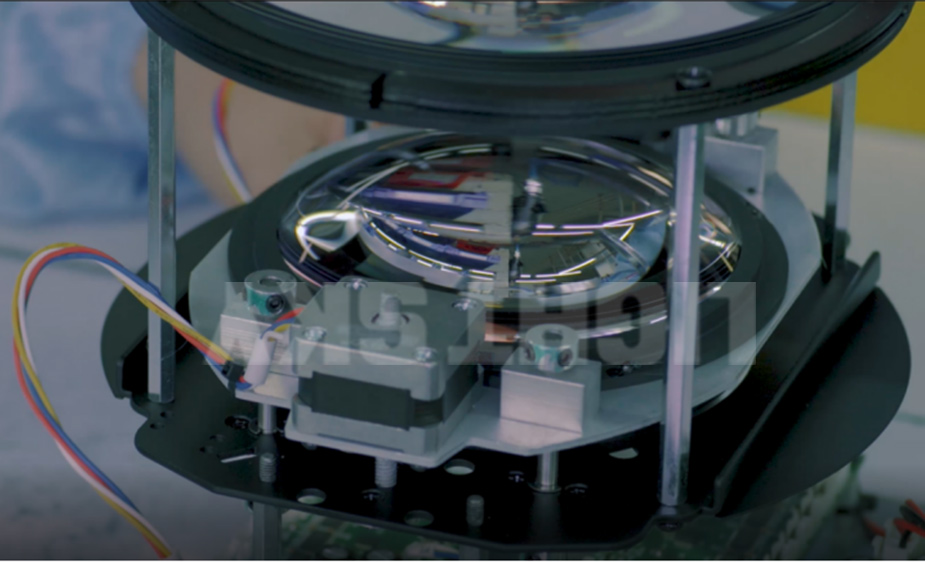

3.How to improve Pan/Tilt positioning accuracy?

To make the Pan/Tilt moves more smooth, more precise, more faster, more smart. LIGHT SKY not only use the top brand motors, but also adopts newest magnetic encoder position technology. For motor’s driver PCB, this encoder is anti-jamming hat can control the Pan/Tilt movement direction accurately.

Step belt’s function for stage lighting like the muscles and bones of human beings. The strong muscles and bones make people quick and powerful. To make the movement of the stage lighting faster and intelligent, longer service life. LIGHT SKY keep improving the belt quality and testing process. Traditional belt installation and calibration mainly reply on technical staff’s experience and intuition, if the belt in loose degree which is easy to cause the Pan/Tilt lose the step. If the belt in tight degree which is easy to damage the belt’s life span even break directly. Therefore, LIGHT SKY has introduced belt loose and tightness tester insure each lighting fixture’s belt in the production line are got tested. In this way, although the working hours are increased, the result is excellent.

4.Details make a difference

It is called silicone tube which is to protect the lighting fixture from shock and screws falling. In the past, the silicon tube was cut by the hand which was not only low efficiency, but also easy to cut the tube in different length. So, LIGHT SKY has invented automatic silicone tube cutting machine which is not only high efficiency, but also cut all the tube in standard size. Although it is a small part from this we can see our engineers’ exploration of improving standardization production.

In order to solve the LED Bin color issue in different production batches, LIGHT SKY has introduced the most advanced color calibration system of the industry which can make sure the colors of the different batches of products are completely consistent. The function of the system is accurate, efficient and stable as small as the installation of a screw.

We also try to achieve system control by inputting the best tested data into the screw torque control system. So, when the worker install the screw, the torque is completely accurate which can avoid the screw loosening and slipping caused by personal differences.

5.How to improve and upgrade the workshop?

To improve and upgrade the workshop, LIGHT SKY has introduced the most advanced intelligent industrial management system built the dust-free workshop and realized the visual operation of the production orders. The production progress of plan number completion amount and rate are clear at one glance. The wind shower room anti-static bracelet abnormal alarming etc which help LIGHT SKY realized from traditional production line to full-automatic production line from low protection to dust-free, from man-made to intelligent. The introduction of E-sop operation instruction makes every step of operation more standard and efficient.

6.How to guarantee the quality and stability of the products?

Even each process meets the standard and every part is assembled properly, there is no guarantee that every lighting fixture 100% work normally. Therefore, the parts need to go through a very strict test before mass production.

The LED light source must work continuously 2000 hours at the temperature of 40℃ and the final light degradation can not over 5%. The key modules and components must undergo 1440 hours of continuous salt spray test the covers would undergo 500 hours of UV protection test. Through the programmable constant temperature test, it can find out how the whole lighting fixture work at minus 20℃ to 45℃ and the humidity of 45%. During the test of spectrometer each photoelectric color parameter must satisfy the standard. After passing the withstand voltage test, electromagnetic radiation and electromagnetic conduction test and relevant transportation vibration and drop test. The product can be put into production line after they are fully qualified.

In workshop production, LIGHT SKY carry out ONE FIXTURE, ONE INSPECTION and more than 4 hours aging for all the fixture. In addition, waterproof lighting fixture’s IP rate test must be finished and qualified.

7.Cases from all over the world

With the spirit of pursuing the perfection of product, LIGHT SKY has been engaged in R&D and production of stage lighting nearly 30 years. From an unknown factory to TOP10 brand in China. Until now, we are still not the most productive company in the industry, but we are the most diligent and honest one. Up to now, we have won more than 200 national patents, China Outstanding Patents Awards. The brand LIGHT SKY has been registered in more than 40 nations. All the product of LIGHT SKY are got CE, ETL and RoHS approval which includes China, United States, Russia, Italy, UK etc. We always believe that this is the best time. As long as you willing to pay, there will be gaining and returning. We are glad to grow up in this great era.

Along the way, we have witnessed the great country style of Hangzhou G20 summit, celebrated the Chinese New Year in CCTV stage, participated Latvian 100th year national day lighting show celebration, brought infinite laughter and surprise to kids in Disney, Beijing Olympic grand ceremony, Guangzhou Asian Game, Shanghai World Expo, Guangzhou Lighting Festival, Eurovision 2016, Sydney Vivid Lighting Festival, Rome Center Theatre in Italy, Freiburg Concert Hall in Germany etc.

8.Representative products

We ont only focus on the skills at hand, but also see the changes of the time, forecast the product new tendency, brought by the consumption and technology. We endure the loneliness day and night in the process of innovation and also gain the achievement and pleasure of leading, the development and reform of the industry.

IP3000 (AUQABEAM) was the pioneer of the industry which was the first waterproof discharge lamp fixture in the world.

BUMBLEBEE series moving beam with its high brightness, low power consumption, compact and fast features make it popular in gobal performance market.

IP3500 (SHARK) series with IP66 rate protection, sand-proof, dust-proof, water-proof features make the outdoor permanent installation moving head fixture say goodbye to heavy rain cover.

SHARK400/ SHARK450/ SHARK LASER

AQUABEAM400LL (the upgrade version of AQUABEAM)

F230II (the 2nd generation of Bumblebee)

We do not have extraordinary creative talent, but we are willing to spend more time and cost to try to change refine ideas, and research products. We did not do a lot of advertising, but we spared no effort on the products. We believe that the word-of- month accumulated by the real materials is more valuable than advertising. We know that there must be a group of craftsmen’s persistence and dedication behind the top quality lighting fixture. Because of staffs contribution and dedication that LIGHT SKY can build a strong quality great wall. We insist that stick to every routine and perfect every detail in the production line are as important as creation.

Above, are what we are understanding of how to be. BE THE NEXT TOP!