TIPS for stage lighting package?

As we all know, packaging is very important for stage lighting , as the fixture for stage usually are complicated and frangible , we must design a durable package to protect it from transportation violence.

Product damage during shipping is something no one should have to face. As a manufacturer, we need to provide customers with a good packaging that not only ensures the safety of transportation, but also ensures good stability during use.

What we can do for protect our customers products?How do we reduce this doesn’t happen?

Read on to learn more about LIGHT SKY how to package your products correctly!

1. What factors will affect product packaging?

According to the process, we can clearly know that manufacturer–transportation company–customer.

- Manufacturer

- Transportation

- Customer

2. Why you need to pay attention to packaging–Money and Time!!

We can also best answer the first question from the three aspects.If you don’t pay attention, you will lose money and time.

- Manufacturer

Manufacturers need to consider the reliability and stability of packaging at the beginning of design.Good product packaging design can prevent some unknown problems. It is a key factor that can ensure the smooth progress of logistics to a certain extent. This includes issues with the materials used, the design of the packaging itself or the storage of the box before shipping, and protection in transit.

It helps avoid delays caused by non-compliance to package regulations and local and international shipping standards.

It protects products to ensure goods survive transport undamaged.

It makes handling and transporting your goods convenient.

- Transportation:Choose a transportation company with good quality and service, with Friendly Shipping Products.Don’t just choose low prices without service guarantees.

- Customer:Good usage habits and regular maintenance.

3. What is safe packaging?

We can define what is safe packaging in some ways:

The packaging can protect the contents during the shipment journey; and the package must withstand various external factors such as liquids, bending, damage, and exposure to weather conditions.

- Choose suitable packing materials.

Packages pass through many hands during their journey to the customer. With this in mind, the material chosen should be soft but strong enough to withstand the transfer from one transportation stage to the next .

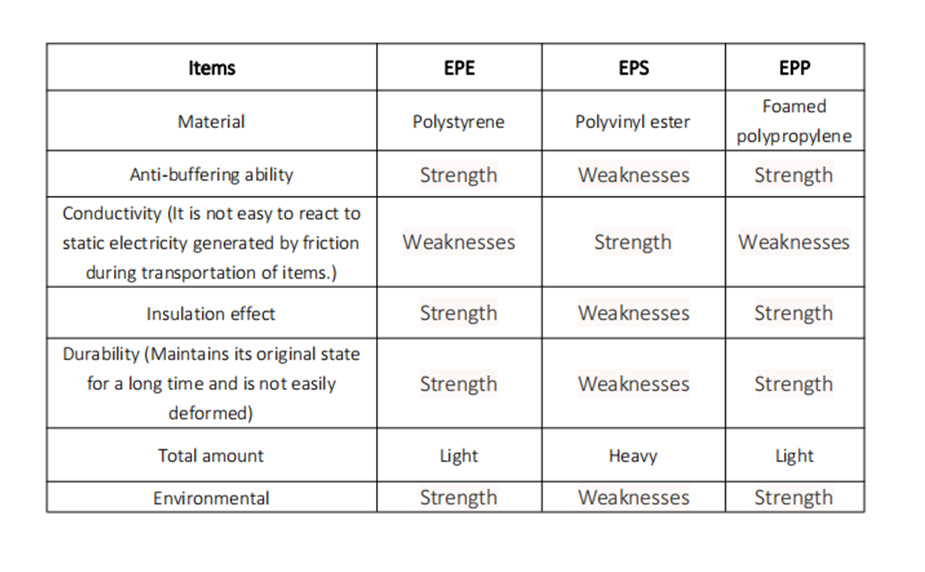

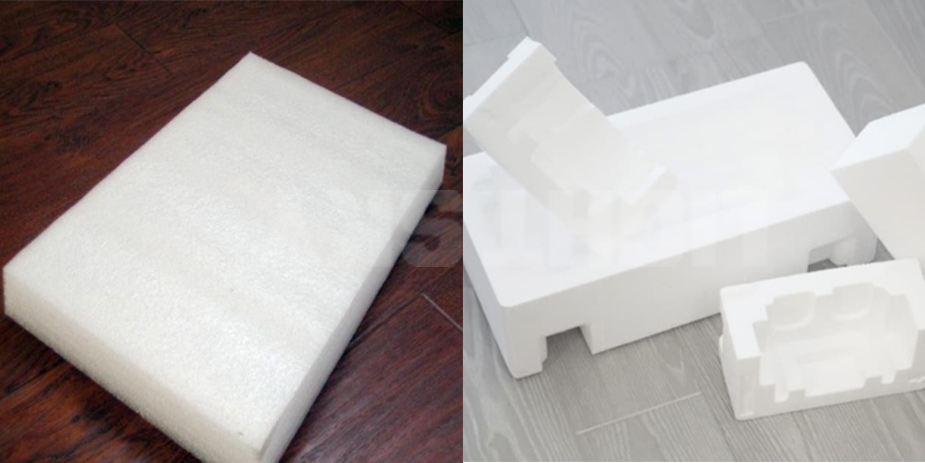

We commonly use two packaging materials: EPS(Expanded Polystyrene)and EPE (Expandable Polyethylene).

EPE is used for light fixtures with a small weight, and EPS is used for light fixtures with a heavy weight.

- The practicality of simulation testing packaging

LIGHT SKY have two package testing equipment. Before any new product’s mass production, the sample product need to have a drop test and a moving test. According to the drop test, we can see if the package strong enough to protect the fixture from damage. And this machine can simulate the movement of the goods in vehicle. Which can check if the internal parts are stable. We must prevent the situation that the screw drop out when transportation.You can check the video at YouTube.

- Packaging method is also very important

It often happens that the outer packaging of equipment is damaged due to changes in external weather and environment.

For example, in rainy and snowy weather, we wrap a rainproof film on the surface of the packaging to prevent the outside of the packaging from being unsightly due to liquid contamination.

4. SUSTAINABILITY AND REUSABILITY

Today, consumers are more conscious about their carbon footprint and being green than ever before and the product packaging is at the forefront of their minds. They are becoming increasingly aware of product packaging and the potential damage it could do to the world we live in.

Although packaging can look pretty, if it isn’t reusable or eco-friendly, then consumers may not purchase from the brand again for that very reason. Therefore, it is essential for brands to consider the type of packaging they want to create, with a sustainable future in mind.

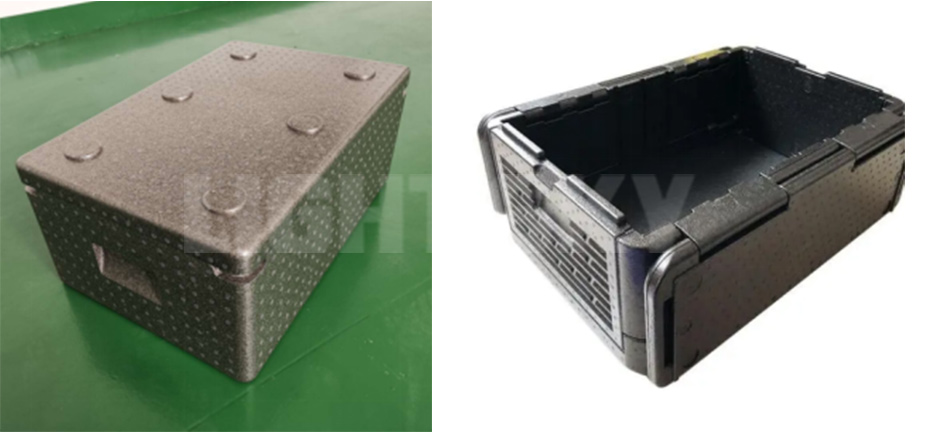

LIGHT SKY will use EPP(Expanded polypropylene) material as filler in future packaging, which has a compact structure, good temperature resistance, low water absorption, good moisture resistance, and tough material without the fragility of Styrofoam.Good buffering performance, it can play a good buffering role even when the cushion layer is not thick.

Being reusable makes it extremely cost-effective.EPP is very suitable for packaging materials for mobile performance equipment.

Our preliminary plan is that flight boxes and cartons are the same. We only need to change the internal materials to obtain different packaging effects. This can not only help customers reduce packaging usage costs, but also shorten the production time of manufacturers.

The only disadvantage of this material is that it is expensive.