The Maintenance and Caring tips of Stage Lighting

With the continuous development of modern science and technology, especially the popularization of LED light source, the computerization and digitization of ordinary lights control technology, and the popularization of computer lights, the development of lighting has a tendency to be unified. Lights are the equipment that lighting designers use most in their daily work, and they are also the direct embodiment of lighting effects. Therefore, the maintenance and care of lighting fixture is particularly important. Specifically, there are some contents as follows.

1.Connection of lighting

Connecting lights is a daily work, and knowing how to connect lights correctly is crucial. This connection includes the connection between the light and the TRUSS, the connection between the lamp and the lamp socket, and the connection between the power cord and the power socket.

First, make sure that the light is firmly mounted on the TRUSS, and check whether the safety rope is firmly tightened. When hanging lights, make sure that the supporting structure and all accessories used can hold at least 10 times the weight of all the equipment they support.

Secondly, pay attention to the connection between the lamp and the lamp socket. It is better to check the condition of the lamp holder before installing the lamp. Do not over-tighten the connection. Use moderate force, otherwise it will cause damage to the lamp connection port, thus affecting normal use. If the lamp is not fixed tightly, it will cause sparks at the contact point, causing damage to the lamp. Poor contact of the lamp will cause overheating at the interface, causing the lamp holder to deform and lose elasticity, and will also cause oxidation of the contact surface or become concave to form a high resistance point, and even damage the lamp.

If the power cord and the power socket are not connected well, local overheating will occur, causing problems with the plug socket, causing fire safety hazards. When connecting the cable, check the plug carefully to make sure it is safe. Cable joints should be locked to reduce potential safety hazards caused by accidental stress on the cables. Lamps must be used at rated voltage and frequency, and grounding conditions of all grounded lamps must be checked regularly.

2. Turning on lights

In order to prevent accidents such as explosions when hot light sources are turned on cold and to extend the service life of the lamps, the console has a preheating function. However, when using the dimming console to turn on the lamps, except when the plot requires all the lamps to be turned on at the same time, it is best to use the push rods to turn them on slowly in groups. For stage lights using high-voltage gas discharge light sources, attention should also be paid to the problem of turning them on in hot states. Since gas discharge bulbs cannot light up quickly in hot states, if they are forced to be turned on, it is easy to damage the starting power supply circuit of the computer light. Therefore, if the lamp requires that it can only be restarted in a cold state, it must be noted that it takes a period of cooling after being shut down before it can be turned on again.

3. Protection of lights in hot state

The surface of most lights will become very hot during use, especially those with heat source. Do not install the fixture onto combustible surface, and keep all combustible materials at least 20 cm away from the fixture. Ensure a minimum clearance of 0.2m around the cooling fans and ventilation. Do not expose the front glass to sunlight or other strong light source from any angle. Lenses can focus the sun’s rays inside the fixture, creating a potential fire hazard.

4. Waterproof protection of lights

Water and electricity are incompatible. Do not underestimate the danger of working in a humid environment. Moisture on the socket and lamp will not only cause leakage and electric shock, but also increase carbon deposits on the insulator, which will cause damage to the equipment and short circuit over time. Some lamps are specially designed for outdoor or underwater use, but most are not. When a general light is used, if water is spilled or falls into the lamp socket, it will cause an explosion and damage the equipment, and even cause personal injury. Therefore, if the light is accidentally flooded, the power supply should be cut off immediately and the lamp should be dried.

5. Inspection and replacement of light sources

All light sources will deteriorate to varying degrees during use, including changes in light intensity and light quality. It is necessary to observe and check the working condition of the lamp at any time and replace it regularly.

Check whether the traditional discharged lamp is partially bulged. Long-term use of the lamp will cause local overheating due to high pressure, too steep burning angle of the lamp, poor ventilation of the lamp, and improper adjustment of the reflector. Local deformation will cause local bulges, which will cause the bulb to explode or be damaged. Regularly check and adjust the use status of the bulb, especially the double-ended computer light high-pressure gas discharge bulb. After a period of use, the use angle should be rotated and the deformed bulb should be replaced.

Check whether the luminous brightness of the light source is normal. The luminous flux of the light source will decay after a period of use. According to the standard, it should be replaced when the luminous flux is only 60% of the initial value. LED lamps that cannot replace the light source should be returned to the factory or scrapped.

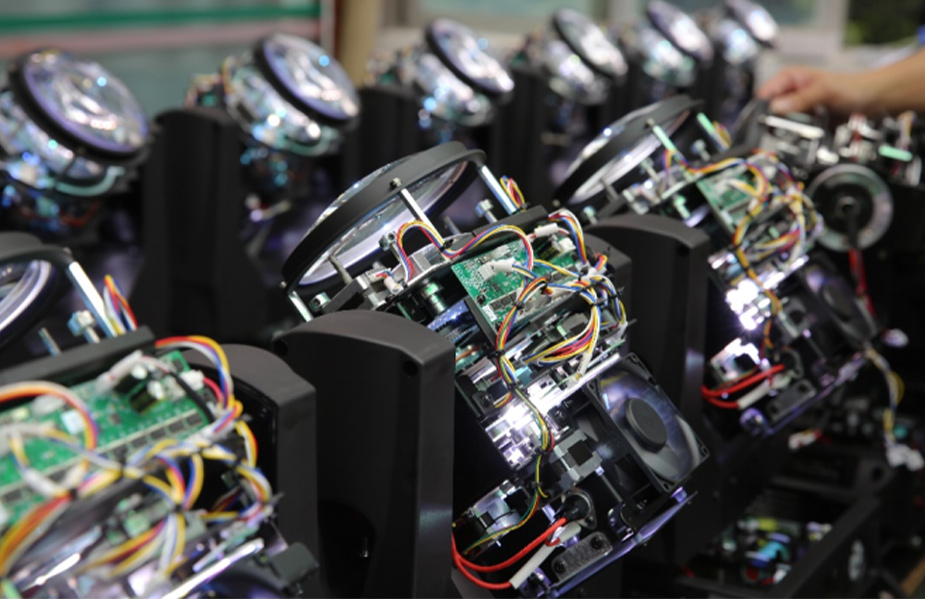

6. Regular maintenance of lights

Lights should be regularly inspected and maintained to ensure normal use. It should be cleaned with warm water or a cloth soaked in soapy water and wrung out. Do not use gasoline or volatile oil. Lights should not be repaired in places with dangerous substances such as gas and steam. Dust behind the light should be cleaned with a dry cloth or duster. The regular maintenance of lights mainly includes the following contents.

Check and remove dust from the lamp body;

Check and replace the power supply line and plug;

Check, repair and replace the lamp hook;

Remove dust from the inside of the lamp body;

Check and maintain the circuit board;

Check and maintain the drive motor;

Check and add oil to the transmission gear;

Check and replace the light source;

Check and wipe the optical lens and reflector;

Check the self-test function.

Please do remember that before starting any maintenance work or cleaning the luminaire, the power supply to the luminaire must be disconnected.

LIGHT SKY is a manufacturer of stage lighting for more than 30 years. We have one of most professional engineer departments. If you have any questions about stage lighting, welcome to contact us. We will give you professional suggestions. Do you want to know more about stage lighting? Welcome to visit the website of LIGHT SKY: https://en.lightsky.com.cn/